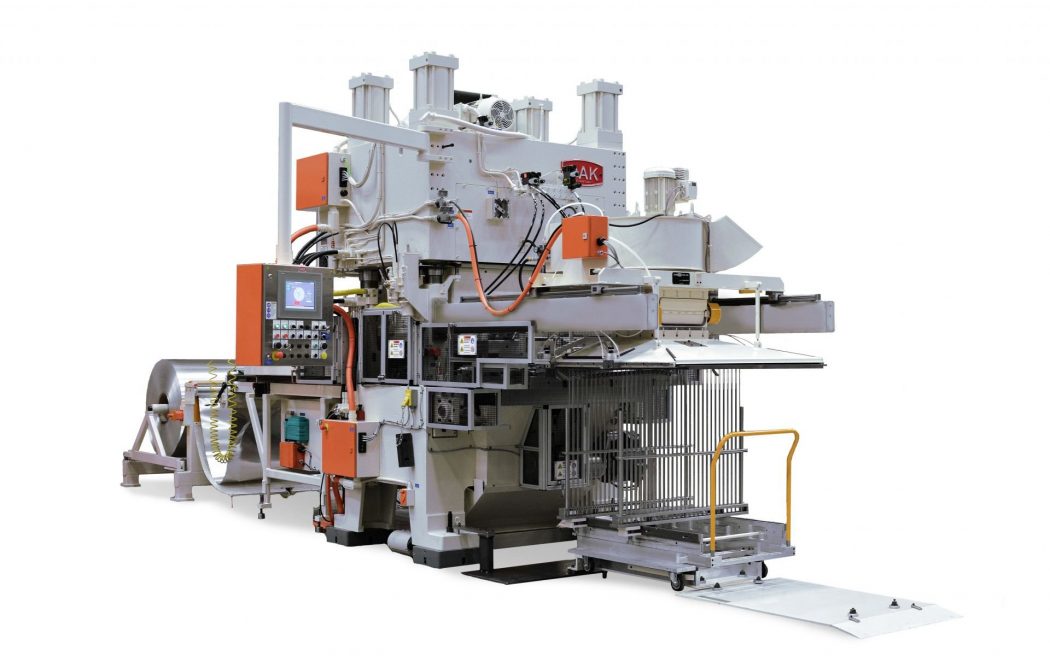

Presses for the HVAC Industry

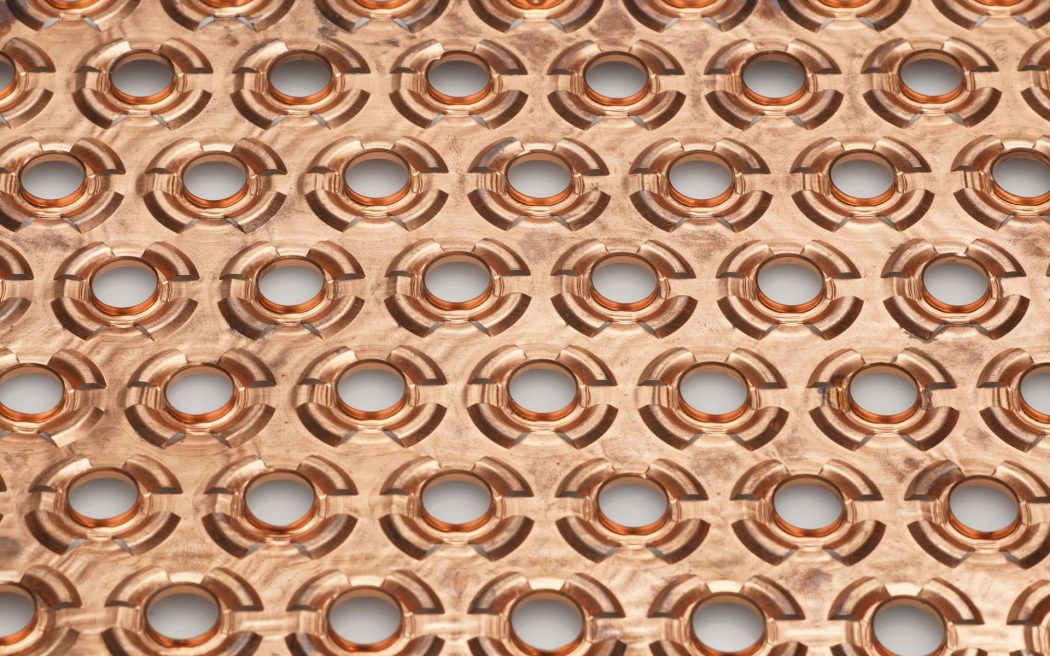

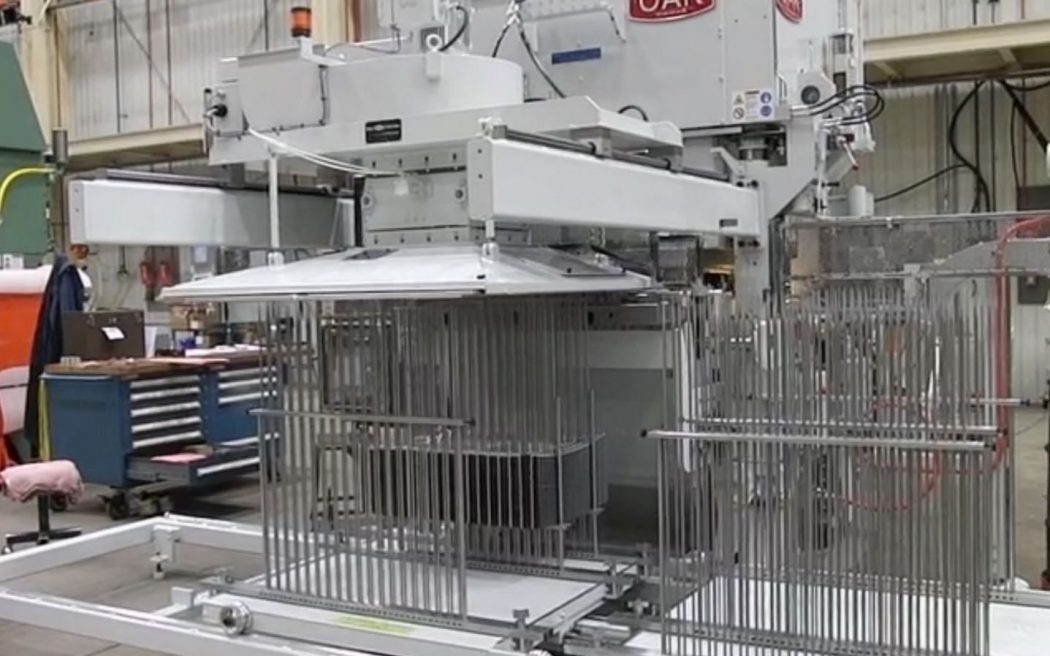

Oak Press presses are the industry standard in the HVAC market where large progressive tools are used to make the air conditioner “fins.” In addition to fin production, OAK Press presses can also be used to make the “end sheets” for the heat exchanger coils.